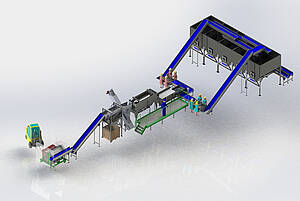

Potato line: From box to bunker (10 t/h)

The line is suitable for a multitude of applications both for packaging factories as well as for processing plants. The depicted line can also be designed with higher throughputs of up to 50 t/h and can be extended with further units.

The produce is supplied in boxes. The produce is conveyed from the semi-automatic box tipper to the soil remover. The soil removed in the soil remover falls into a box. The potatoes are sluiced through the stone separator into the washing machine. The closed water circuit of the stone separator and washing machine guarantees optimum cleaning and destoning with minimum water consumption. The washing machine is followed by a roller dryer and a sorter, which separates the flow of produce into two sizes. Each of the following sections of a production line has a roller inspection table for manual inspection and discharge of unsuitable tubers. After that the produce can be optionally distributed by a system of distribution conveyors into 5 bunkers. Folding chutes are installed in the bunkers for gentle filling. The residual moisture on the potatoes can be dried completely using the ventilation channels in the bunkers. The potatoes are transferred from any required bunkers onto one of both collecting conveyor belts by means of the conveyors integrated into the bunkers. These conveyors represent the connecting module, for example to a packaging machine or further processing stations.